Getting to know about heat transfer paper is not enough. We have to know how to print the designs on it in order to fully understand why it is better. There are different methods of heat transfer printing. For example, Silk-screen printing, flexo printing, and digital printing.

Let’s discuss all these in detail to know more about them.

Different methods of heat transfer printing

Silk-Screen printing

To use this technique of heat transfer printing, we need different materials. Firstly, create a printing frame. In other words, print the design onto a sheet so that easy to transfer the ink. Then, place the frame onto a T-shirt and with the help of a scraper, screen the colours on top. We can only layer of the four colours maximum. When using an ink frame to apply colour, it is always left to dry after so that you can use for another application.

Since silk-screen printing had become very popular recently, the tools needed to use it have also become more modern. With the kind of ink and machinery available now a days, it is easy to obtain super-fine quality and results with printing. It is for this reason that more companies are deciding to go for silk-screen printing when creating T-shirts.

Flexo printing

This printing technique uses a flexible printing plate. These printing plates were made of rubber in the past. Nowadays, businesses use flexible photopolymer printing plates.

Flexo printing is unique from others because it adapts well to different materials. It can also use wider range of inks including water inks and UV inks. Since, it is adaptive, you can print on any type of substrate like, plastic, metal, paper, etc.

Digital printing

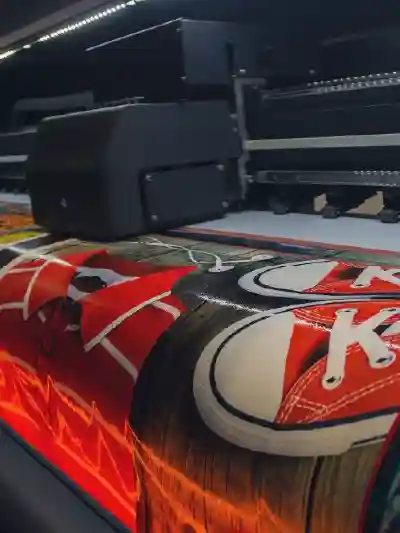

Digital printing is a technique that has an unlimited color feature. Thus, it enables creating virtually seamless designs and images.

Digital printing is of two types: heat transfer and direct printing.

In Heat transfer digital printing heat it apply heat to the ribbon with the printhead. Hence, the material melts in order to form the image. This image becomes a part of the media as to absorb the ink. Thus, giving excellent printing quality. Heat transfer printers can accommodate different mediums like paper, polypropylene materials and polyester.

In Direct digital printing a heated ribbon is not used. They do not use ink and toner as well. Instead, a thermal printhead use to transfer the images to the marked surface. But this transfer is most susceptible to abrasion due to heat and light. Hence, images don’t last very long.

Heat transfer printing is a preferred way to print to on t-shirt in modern times, especially the lables on sports and intimate clothing for performance and comfort purposes. From all the different methods of heat transfer printing, you can get to know and decide which one will suit your business the best in terms on longevity, and budget.

Latest a new kind of digital heat transfer printer is very popular and quite easy to on print heat transfer film and get ready heat transfer designs for any kind of t-shirts. It’s quite thin and soft after heat press on t-shirts, more like screen printing, but much more easy and just print out from your DTF printer in 1 minitue and no any moq request. Seaart offers the DTF printer and also DTF heat transfer film as rolls, A3 and A4 sizes, inks and all accessoires to start your business.

Leave a Reply